While process automation, a core tenet of the transition to Industry 4.0, can minimize or eliminate processing issues associated with a wide range of material variability, some variations require physical alterations to processing equipment to be implemented. In this article segregation issues caused by an API supplier-change are addressed rapidly and efficiently via another pillar of Industry 4.0, additive manufacturing.

At the core of the transition to Industry 4.0 is the drive toward robust, reliable and comprehensive process automation. Three of the nine pillars of Industry 4.0 : Internet of Things, System Integration and Autonomous Robotics are particularly well suited to supporting this objective. With effective and democratised automation delivered by a range of available process digitalisation platforms, processing issues such as those caused by raw material variability from supplier or up-stream processing steps can often be addressed with no quality or time penalties.

Some raw material variations however require more intervention than pure automation tools can provide, instead requiring physical re-configuration of process equipment. In this application another pillar of Industry 4.0, additive manufacturing, can be employed to address certain physical/ equipment issues in shorter timeframes than otherwise possible, ensuring quality is optimally maintained and production schedules can continue to be met.

In this article, a processing issue is discussed in which a change in the supply of Propranolol HCL API resulted in significant challenges coating this API onto substrate pellets in an established Wurster Coating process. When analysed the new-supplier API was found to have a multimodal particle size distribution, as compared to the broadly Gaussian distribution of the original API. This multimodality resulted in significant settling of the coating dispersion even while actively stirred throughout processing. Process and control constraints limited how aggressively this dispersion could be stirred and how much stirrer clearance could be used, ultimately requiring a change to the mixing impeller used.

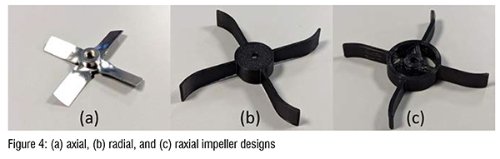

“Standard” axial and radial impeller types were both trialed but solids separation issues were identified for each in their respectively weaker mixing areas. Ultimately a hybrid radialaxial or “raxial” impeller was designed and rapid-prototyped via FDM printing. This impeller was determined to resolve the separation issues identified as well as significantly improve impeller performance against secondary design objectives, allowing for further optimisation of the real-time process automation.

The author’s company operates a process application and contract research laboratory in Dublin, Ireland. This lab provides a wide range of non-GMP development-scale pharmaceutical processing operations including crystallisation, fluid bed (drying, granulation and coating), twin-screw granulation / extrusion, and compression. A suite of accompanying analytical instruments is also available. As part of ongoing partner-research on advanced control of fluid bed Wurster coating, a series of experiments were to be conducted involving the API coating and subsequent functional coating of a variety of sizes of sucrose pellet cores.

Since previous experimental campaigns, a fresh supply of API (Propranolol HCL) had been sourced from a new supplier (Supplier B), meeting an equivalent material specification to that which had been used previously. All other materials and mixing parameters remained unchanged. The impeller used was an axial design.

In executing the first of these API-layering batches a similar automated process control strategy was followed to that which had been used in previous experimental campaigns. The process scientist monitoring the batch noted however that a significant sludgy deposit remained around the outer edge of the coating dispersion beaker base when the API & binder dispersion had been fully sprayed. In the execution of a subsequent batch, the contents of the dispersion beaker were carefully monitored with solids settling noted despite an increase in stirrer RPM. Assay results for these batches confirmed API concentrations below 80% indicating significant losses. On a subsequent batch, a radial-design impeller was trialed with some improvement, however deposits still remained on the bottom of the beaker.

To investigate the root cause of the observed solids sedimentation, a sample from each API batch (Supplier A and Supplier B) was analysed for particle size distribution (PSD) and morphology at the University of Limerick.

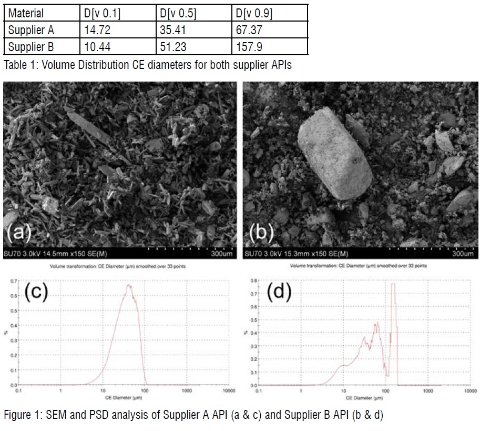

A visual examination was first conducted by Scanning Electron Microscopy (SEM) at multiple magnifications. The results confirmed differences in the physical characteristics / morphological features of both API samples. API from Supplier A was found to be more needle-like in appearance Figure 1a, while the API from Supplier B appeared more cubic in shape Figure 1b, indicating the two samples are likely different polymorphic forms.

PSD analysis was conducted on both samples using Malvern’s Morpholgi G3 particle characterisation instrument. Significant differences were again observed for both API samples. The volume distribution from Supplier A Figure 1c produced a typical Gaussian curve while Supplier BFigure 1d produced a multi-modal distribution curve with a larger maximum particle size.

These differences in particle size, distribution and shape morphology between the API batches would contribute to differences in mixing behaviors observed for the two API coating dispersions under similar mixing conditions. The difficulties experienced maintaining the API from Supplier B in suspension are therefore likely due to the greater percentage of larger particles present, represented by the visible right-hand spike in CE diameter values.

In an initial attempt to resolve the observed settling issue the axial impeller previously used was swapped for a radial impeller which altered the location of observed deposits, but was similarly unable to effectively homogenize the dispersion without the use of excessive mixing speed. Several additional constraints existed on the process in question beyond the core need to effectively homogenize the dispersion, exacerbating the mixing challenges.

The following optimisation objectives were drawn from the identification of the processing issue and the constraints above:

An optimum impeller design should:

With neither of the tested impellers delivering acceptable mixing performance it was decided that as an experiment an impeller should be designed and produced via additive manufacturing to address the areas of weaker mixing performance observed for each of the impeller designs already tested. To quantify the success level of any rapidly developed impeller solution however, a similarly rapid testing methodology would be required to allow comparative performance data to be generated and analysed.

A simple test was devised whereby a full coating dispersion beaker was elevated on a scale to allow clear visibility of the sides and underside. No agitation was applied for approximately 5 minutes, after which time the majority of solids had settled out of dispersion. After this time the impeller under test, positioned with 6mm clearance to the bottom of the beaker was started at an initial low RPM, and gradually increased until all settled material had been re-suspended. The average vertical force caused by the impeller at this “minimum re-suspension RPM” was also noted. Finally, the areas in which settled solids deposits were last to re-suspend were noted for each impeller design as an indication of the distribution of mixing effectiveness

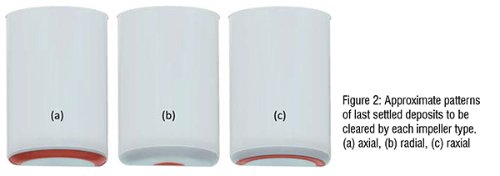

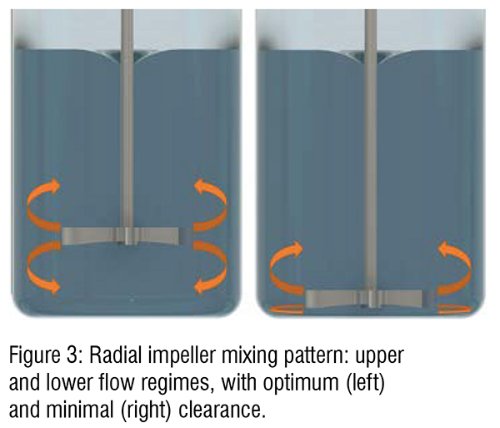

As can be observed in Figure 2 a & b the distributions of mixing effectiveness of the axial and radial impellers could be considered complimentary, with the axial impeller clearing the center-bottom of the beaker more effectively, and the radial impeller clearing the outer bottom more effectively. It was theorized that the weakness of the radial impeller resulted from the lower flow regime being effectively stalled due to the minimal impeller clearance as shown in Figure 3. It was thought that by introducing an axial flow component at the center of an otherwise radial impeller, this mixing dead-zone could be reduced or eliminated. Effectively reversing the typical flow direction of the lower flow regime of the radial impeller and solving the dead zone created by the minimal clearance. This concept of a hybrid radial and axial impeller approach was termed a “raxial” impeller.

A prototype of this raxial impeller was designed in Autodesk Fusion 360, sliced with PrusaSlicer V2.4.2, and printed in ColorFabb HT on an enclosed Prusa i3MK3S+. A parametric design was employed to allow the area ratio between axial (central) and radial (outer) components to be easily varied in future iterations. This was to allow for easy optimisation in future for use in suspensions with differing properties. An initial effective area ratio of 1:12 was chosen. Total design and printing time to deliver this prototype solution was approximately 90 minutes.

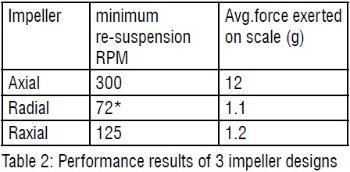

All three impeller designs were tested using the method outlined above. Results can be seen inTable 1, with the approximate distribution of settled deposits which were last to re-suspend shown in Figure 2.

* 72 RPM technically resuspended all settled material but failed to effectively homogenize the suspension, with a visible higher density area between the center of the impeller and the bottom of the beaker, and visible stratification in the suspension density. This is likely due to the lesser vertical mixing effect of a radial impeller as compared to axial. Based on this the radial impeller could not be considered to have met the primary objective of effectively mixing the API solution for spraying.

In terms of force exerted on the scale, the radial impeller tested was noted to be superior to the axial, likely due to its force on the dispersion being primarily exerted in the horizontal plane, as compared to the axial impellers force being exerted along its vertical axis. The raxial impeller’s axial flow component likely adds slightly to the force it exerts, but could be considered a worthwhile design compromise to eliminate the radial impeller’s mixing dead-zone.

As can be seen from Table 1 the 3D printed raxial impeller scored considerably better than the axial design for both minimum RPM and force on the scale, while maintaining all API particles in suspension and visually achieving similarly effective inter-mixing throughout the suspension beaker.